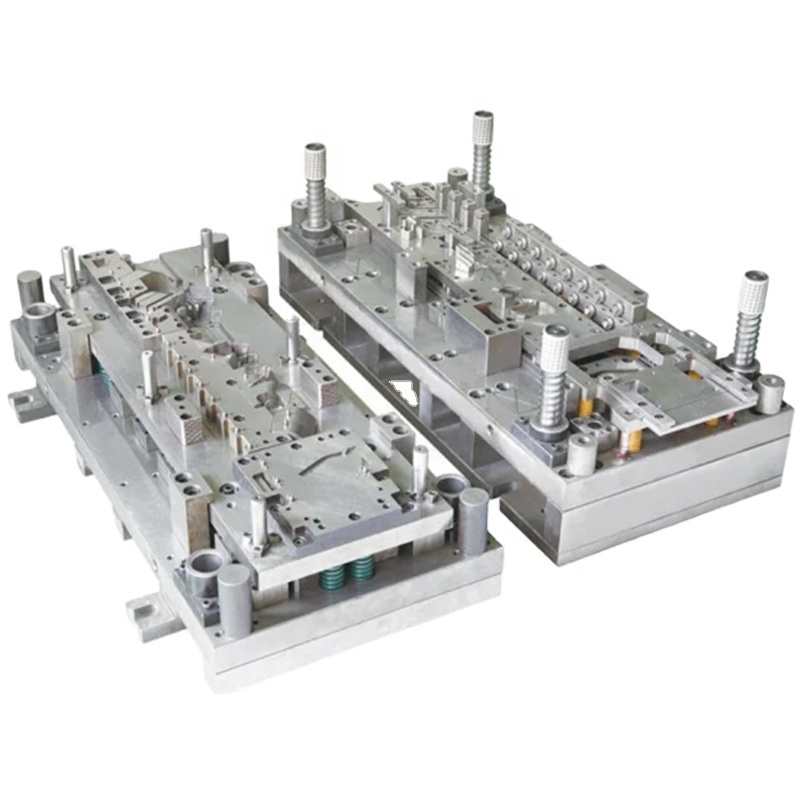

Professional Stamping Metal Molds

Professional stamping metal molds, also known as metal stamping dies or tooling, are precision tools used in the metal stamping or pressing process. These molds are designed to shape and cut sheet metal or other materials into specific forms and designs. Metal stamping is a widely used manufacturing......

Send Inquiry

Product Description

Professional stamping metal molds, also known as metal stamping dies or tooling, are precision tools used in the metal stamping or pressing process. These molds are designed to shape and cut sheet metal or other materials into specific forms and designs. Metal stamping is a widely used manufacturing method for creating various metal components and parts used in a variety of industries, including automotive, aerospace, electronics, and more.

Here are key characteristics and aspects of professional stamping metal molds:

1. Materials: Metal stamping molds are typically made from hardened tool steel, which can withstand the high pressures and wear associated with the stamping process.

2. Tool and Die Sets: Professional stamping molds consist of a combination of upper and lower parts, known as the punch and die, respectively. The punch is the part that contacts the metal, while the die provides the desired shape and cut.

3. Complex Geometries: Stamping molds can be designed to create a wide range of shapes and geometries, including holes, bends, embossing, and more. These molds enable the precise production of intricate components.

4. Precision Tolerances: Stamping molds are created with extremely tight tolerances to ensure the accurate and consistent production of parts. They are often machined to high precision using computer-controlled machinery.

5. High Volume Production: Stamping is well-suited for high-volume production, making it cost-effective for industries that require large quantities of identical or similar parts.

6. Automated Presses: The stamping process is often carried out using automated stamping presses, which apply significant force to the metal and follow precise tool paths to form and cut parts.

7. Progressive Die Stamping: In progressive die stamping, a single mold can perform multiple operations in a single pass, increasing efficiency and reducing production time.

8. Blanking and Piercing: Stamping molds can be designed for blanking (cutting a part from a metal sheet) and piercing (creating holes or openings in a part).

9. Embossing and Coining: These processes involve creating raised or indented patterns or designs on the metal surface and require specialized stamping molds.

10. Quality Control: Precision is crucial in stamping, and quality control measures are essential to ensure that parts meet specifications and standards.

Professional stamping metal molds are used to create a wide range of products, including automotive components, electronic connectors, appliance parts, hardware, and more. The stamping process offers advantages in terms of efficiency, cost-effectiveness, and the ability to produce large quantities of parts with consistent quality. The design and construction of the stamping molds are critical to the success of the manufacturing process.